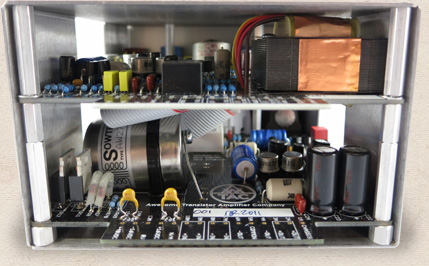

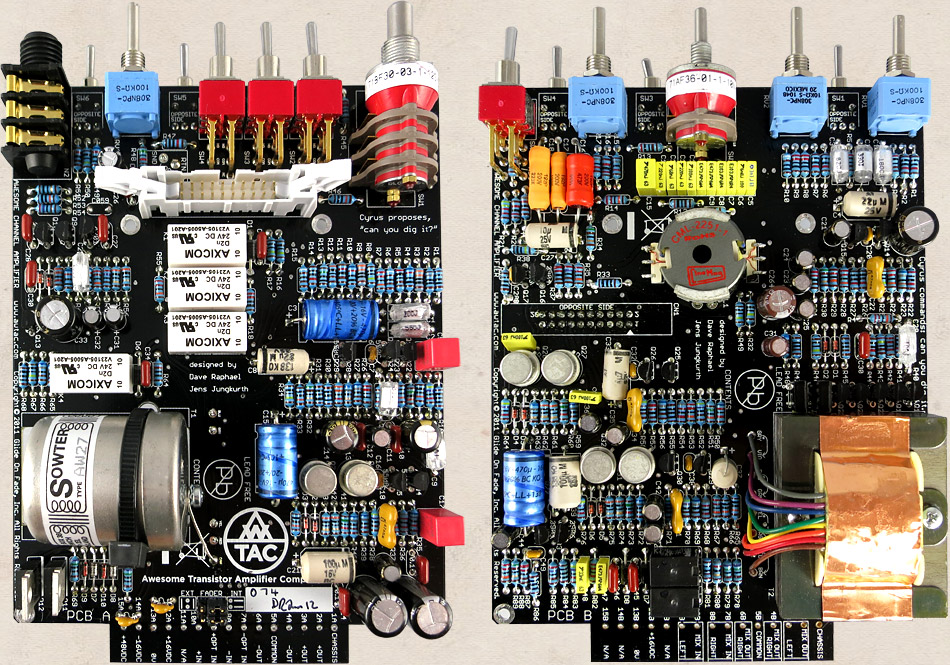

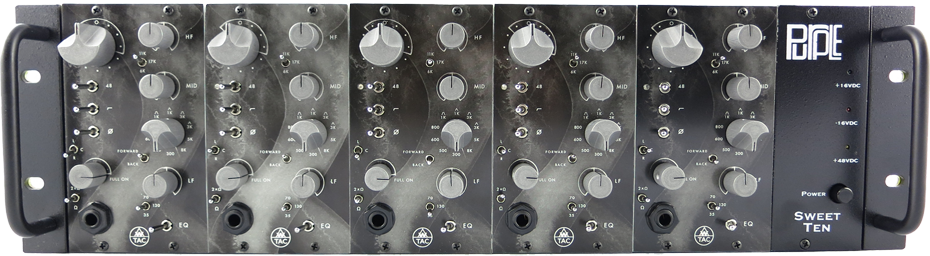

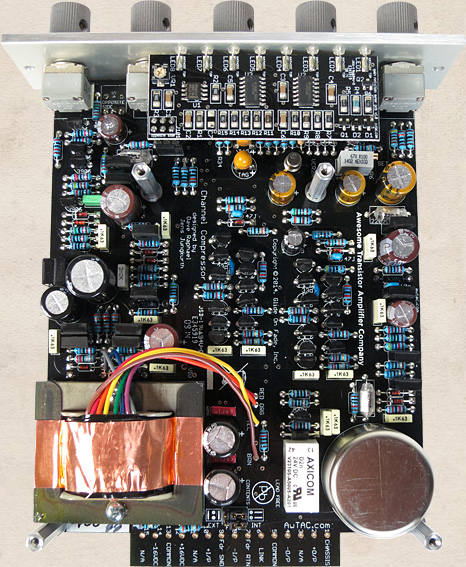

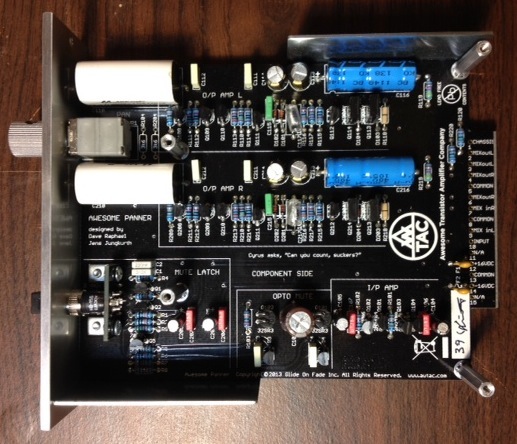

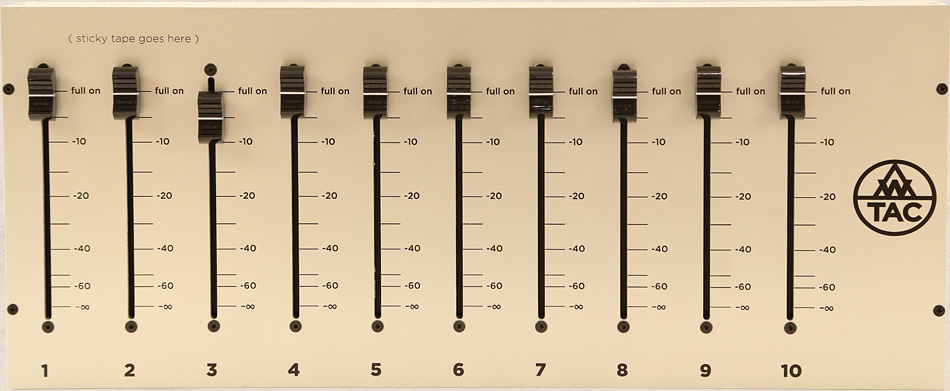

Eisen Audio’s owner, Jens Jungkurth, also heads Design Engineering for Awesome Transistor Amplifier Company (AwTAC). Together with AwTAC President, Dave Raphael, Jens helped develop the flagship Channel Amplifier product. Major contributions to all areas of product development, design-for-manufacture, and quality assurance were provided. Jens and Dave spent countless hours refining the circuits implementation and no-compromise component selection for this processor, and they consider the resulting sound quality to be an infallible artistic statement, on par with several classics.

For details and sales please visit http://awtac.com/products/awesome-channel-amplifier